Unit: AM/FM Stereo Receiver

Manufacturer: Sony

Model: STR-7065

SN: 818755

Today I'm showing a vintage Sony STR-7065 receiver that came in for restoration. This model was manufactured from 1972 to 1974. It delivers 60 watts per channel into 8 ohms with a total harmonic distortion of no more than 0.2%. The damping factor at 8 ohms is 50. The retail price in 1973 was $459.50 (Ref. High Fidelity, May 1973, page 30). A very good review of this model was published a year later in High Fidelity Magazine (January 1974, page 52).

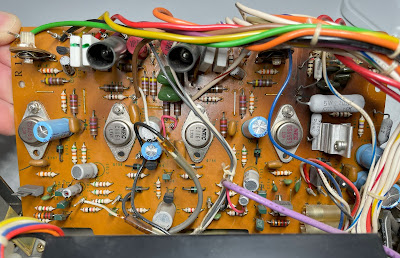

Power Amplifier/Power Supply Board

The power amplifier circuit has 9 aluminum electrolytic capacitors: C701, C703, C706, C707, C711, C751, C753, C756, and C757.

Two ordinary aluminum e-caps C701 and C751 installed in the input signal path were replaced with low leakage Nichicon UKL caps to reduce the noise generated in the circuit. The remaining aluminum e-caps were replaced with low-impedance Nichicon UPW capacitors.

The original e-caps were tested with an Atlas ESR70 capacitance meter; the results are below.

Test results on original capacitors removed from the power amplifier circuit:

C701: rated capacitance – 3.3uF, measured – 4.3uF, ESR – 2.3Ω, deviation: +30%

C751: rated capacitance – 3.3uF, measured – 4.3uF, ESR – 2.2Ω, deviation: +30%

C703: rated capacitance – 100uF, measured – 102uF, ESR – 0.61Ω, deviation: +2%

C753: rated capacitance – 100uF, measured – 110uF, ESR – 0.54Ω, deviation: +10%

C706: rated capacitance – 3.3uF, measured – 4.4uF, ESR – 2.2Ω, deviation: +33%

C756: rated capacitance – 3.3uF, measured – 3.7uF, ESR – 2.8Ω, deviation: +12%

C707: rated capacitance – 47uF, measured – 51uF, ESR – 0.58Ω, deviation: +9%

C757: rated capacitance – 47uF, measured – 48uF, ESR – 0.54Ω, deviation: +2%

C711: rated capacitance – 100uF, measured – 110F, ESR – 0.41Ω, deviation: +10%

The first stage of the power amplifier circuit comprises a differential amplifier consisting of two amplifying transistors with a common emitter: Q702 & Q703 (left channel) and Q752 & Q753 (right channel). The original transistors installed in these positions are OEM Sony 2SA705. These transistors are not on my list of notorious transistors prone to failure. Therefore, I had no intention of replacing these Sony OEM transistors in the differential amplifier until I measured the DC offset in both channels. The DC offset in the left channel was approximately 23mV, which is not ideal but still falls within an acceptable range. However, the DC offset measured in the right channel was around 65mV, which is relatively high.

The most common cause of high DC offset is a significant mismatch between the two transistors of a differential pair. Ideally, both transistors should have perfectly matched. In the real world, a match within 2% is the factory standard (or at least it should be). A relatively small mismatch can be compensated for by a trimmer, thus keeping the DC offset small. However, there are no trimmers on this model to adjust the DC offset for each channel. Therefore, I decided to unsolder both differential pairs and assess their matching. Below are the testing results for the original Sony 2SA705 transistors from each channel.

Test results on OEM Sony 2SA705 transistors

Q702 (left channel): hfe - 165, Vbe - 0.750V

Q703 (left channel): hfe - 163, Vbe - 0.745V

Q752 (right channel): hfe - 161, Vbe - 0.748V

Q753 (right channel): hfe - 145, Vbe - 0.747V

The mismatch between the two transistors in the left channel is only 1%, resulting in a relatively low DC offset of around 23mV. In contrast, in the right channel, the mismatch between the two transistors is approximately 11%. This level of mismatch is relatively high and leads to a high DC offset of about 65mV.

As a solution, I chose to replace all OEM transistors with new Fairchild KSA992 transistors. Before installation, each pair of KSA992 transistors was meticulously matched for current gain and base-emitter voltage. Consequently, the DC offset in the left channel reduced to approximately 14mV, and in the right channel, it dropped to around 10mV (refer to the images in the "Power Amplifier Adjustment" section).

Test results on new closely matched KSA992 transistors

Q702 (left channel): hfe - 399, Vbe - 0.758V

Q703 (left channel): hfe - 401, Vbe - 0.756V

Q752 (right channel): hfe - 405, Vbe - 0.758V

Q753 (right channel): hfe - 405, Vbe - 0.754V

The original pre-driver transistors (Q705 and Q755) installed in the power amplifier circuit are Sony 2SC1124. The current gain in this transistor often deteriorates with age and should be replaced with a modern substitute. I replaced both original pre-driver transistors with Fairchild KSC2690. Watch the pinout on replacement transistors. The original transistor is EBC and the new one is ECB.

The power supply circuit has 4 aluminum electrolytic capacitors: C805, C806, C816, and C817. All of them were replaced with low impedance Nichicon UPW capacitors.

Test results on original capacitors removed from the power supply circuit:

C805: rated capacitance – 330uF, measured – 376uF, ESR – 0.21Ω, deviation: +14%

C806: rated capacitance – 330uF, measured – 418uF, ESR – 0.13Ω, deviation: +27%

C816: rated capacitance – 47uF, measured – 55uF, ESR – 0.32Ω, deviation: +17%

C817: rated capacitance – 47uF, measured – 57uF, ESR – 0.18Ω, deviation: +21%

Three 1/4W carbon resistors (R803, R805, and R806) are surrounded by wirewound resistors that run very hot under normal working conditions. I noticed that the body of one carbon resistor (R803) was damaged, possibly due to the extensive heat generated by the 5W wirewound resistor R802. Consequently, I decided to replace all three original 1/4W carbon resistors with new 1/2W KOA Speer metal film resistors to enhance the reliability of the power supply circuit.

Power amplifier/power supply board - before and after

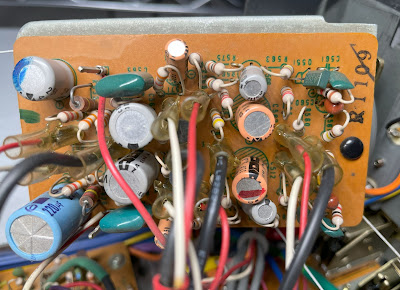

Control Board

The control amplifier board is quite difficult to service due to the many wires that block access to electronic components. Also, several electrolytic capacitors on this board are located too close to the front panel and are difficult to get for replacement.

Pre-Amplifier Circuit

The pre-amplifier circuit has 2 solid tantalum capacitors (C501, C551) installed in the input signal path, 2 low leakage e-caps (C502, C552) installed in the feedback loop, 2 low leakage e-caps (C508 C558) installed in the output signal path, one aluminum electrolytic capacitor C810 installed in the bias loop, and 2 filtering aluminum e-caps (C811, C812).

The original solid tantalum and two low leakage capacitors (C502, C552) were replaced with modern low leakage Nichicon UKL caps. The other two low leakage e-caps installed in the output signal path were replaced with high-quality film polyester WIMA caps. The original e-cap C810 was also replaced with a film polyester WIMA cap. The remaining filtering capacitors are replaced with low impedance Nichicon UPW capacitors.

Test results on original capacitors removed from the pre-amplifier circuit:

C501: rated capacitance – 3.3uF, measured – 3.5uF, ESR – 0.92Ω, deviation: +6%

C551: rated capacitance – 3.3uF, measured – 3.6uF, ESR – 0.94Ω, deviation: +9%

C502: rated capacitance – 33uF, measured – 37uF, ESR – 1.12Ω, deviation: +12%

C552: rated capacitance – 33uF, measured – 35uF, ESR – 1.27Ω, deviation: +6%

C508: rated capacitance – 0.47uF, measured – 0.46uF, ESR – N/A, deviation: -2%

C558: rated capacitance – 0.47uF, measured – 0.51uF, ESR – N/A, deviation: +9%

C810: rated capacitance – 0.47uF, measured – 0.49uF, ESR – N/A, deviation: +4%

C811: rated capacitance – 220uF, measured – 222uF, ESR – 0.32Ω, deviation: +1%

C812: rated capacitance – 220uF, measured – 235uF, ESR – 0.26Ω, deviation: +7%

Flat Amplifier Circuit

The flat amplifier circuit has 2 solid tantalum capacitors (C603, C653) installed in the input signal path, 4 aluminum electrolytic capacitors (C604, C654, C608, C658) installed in the input signal path, 6 aluminum e-caps (C613, C663, C618, C668, C619, C669) installed in the output signal path, 2 aluminum e-caps (C609, C659) installed in the feedback loop, one aluminum electrolytic capacitor C813 installed in the bias loop, and 2 filtering aluminum e-caps (C814, C815).

The original solid tantalum capacitors, and all ordinary aluminum e-caps installed in the signal path were replaced with low leakage Nichicon UKL caps. The original e-cap C813 was replaced with a film polyester WIMA cap. The remaining filtering capacitors are replaced with low impedance Nichicon UPW capacitors.

Test results on original capacitors removed from the plat amplifier circuit:

C603: rated capacitance – 3.3uF, measured – 3.5uF, ESR – 0.86Ω, deviation: +6%

C653: rated capacitance – 3.3uF, measured – 3.5uF, ESR – 0.98Ω, deviation: +6%

C604: rated capacitance – 3.3uF, measured – 4.1uF, ESR – 2.6Ω, deviation: +24%

C654: rated capacitance – 3.3uF, measured – 3.9uF, ESR – 2.4Ω, deviation: +18%

C608: rated capacitance – 10uF, measured – 12uF, ESR – 0.89Ω, deviation: +20%

C658: rated capacitance – 10uF, measured – 12uF, ESR – 1.03Ω, deviation: +20%

C609: rated capacitance – 47uF, measured – 49uF, ESR – 1.36Ω, deviation: +4%

C659: rated capacitance – 47uF, measured – 51uF, ESR – 1.29Ω, deviation: +9%

C613: rated capacitance – 3.3uF, measured – 3.7uF, ESR – 2.71Ω, deviation: +12%

C663: rated capacitance – 3.3uF, measured – 4.4uF, ESR – 2.12Ω, deviation: +33%

C618: rated capacitance – 3.3uF, measured – 4.1uF, ESR – 1.94Ω, deviation: +24%

C668: rated capacitance – 3.3uF, measured – 3.8uF, ESR – 1.89Ω, deviation: +15%

C619: rated capacitance – 3.3uF, measured – 3.8uF, ESR – 1.73Ω, deviation: +15%

C669: rated capacitance – 3.3uF, measured – 3.6uF, ESR – 2.21Ω, deviation: +9%

C813: rated capacitance – 1uF, measured – 1.2uF, ESR – 1.65Ω, deviation: +20%

C814: rated capacitance – 100uF, measured – 112uF, ESR – 0.42Ω, deviation: +12%

C815: rated capacitance – 100uF, measured – 118uF, ESR – 0.41Ω, deviation: +18%

Noise Elimination Circuit

The noise elimination circuit for the tuner section has 2 aluminum electrolytic capacitors: C809 and C823. I replaced them with low leakage Nichicon UKL caps.

Test results on original capacitors removed from the noise elimination circuit:

C809: rated capacitance – 3.3uF, measured – 3.7uF, ESR – 2.62Ω, deviation: +12%

C823: rated capacitance – 3.3uF, measured – 4.1uF, ESR – 1.96Ω, deviation: +24%

Audio Muting Circuit

The audio muting circuit has 2 aluminum electrolytic capacitors: C807 and C808. I replaced them with low impedance Nichicon UPW capacitors.

Test results on original capacitors removed from the audio muting circuit:

C807: rated capacitance – 100uF, measured – 115uF, ESR – 0.93Ω, deviation: +15%

C808: rated capacitance – 47uF, measured – 61uF, ESR – 0.42Ω, deviation: +30%

Below are a couple of photos of the control board before and after service (sorry, due to a bunch of different wires, I was not able to take better pictures of this board).

Control board - before servicing

Microphone Amplifier Board

The microphone amplifier board has 2 solid tantalum capacitors (C510 & C560), 4 low leakage e-caps (C512, C513, C562, C563), and 6 aluminum electrolytic capacitors (C514, C516, C564, C566, C820, C821). The original solid tantalum and low leakage capacitors installed in the signal path were replaced with modern low leakage Nichicon UKL caps. The remaining aluminum e-caps were replaced with low impedance Nichicon UPW capacitors.

Test results on original capacitors removed from the microphone amplifier board:

C510: rated capacitance – 3.3uF, measured – 3.5uF, ESR – 2.6Ω, deviation: +6%

C560: rated capacitance – 3.3uF, measured – 3.0uF, ESR – 3.1Ω, deviation: -9%

C512: rated capacitance – 33uF, measured – 38uF, ESR – 0.94Ω, deviation: +15%

C562: rated capacitance – 33uF, measured – 38uF, ESR – 0.96Ω, deviation: +15%

C513: rated capacitance – 3.3uF, measured – 4.9uF, ESR – 2.1Ω, deviation: +48%

C563: rated capacitance – 3.3uF, measured – 4.8uF, ESR – 2.2Ω, deviation: +45%

C514: rated capacitance – 100uF, measured – 115uF, ESR – 0.48Ω, deviation: +15%

C564: rated capacitance – 100uF, measured – 117uF, ESR – 0.38Ω, deviation: +17%

C516: rated capacitance – 10uF, measured – 10uF, ESR – 1.1Ω, deviation: 0%

C566: rated capacitance – 10uF, measured – 10uF, ESR – 1.3Ω, deviation: 0%

C820: rated capacitance – 47uF, measured – 48uF, ESR – 1.12Ω, deviation: +2%

C821: rated capacitance – 220uF, measured – 194uF, ESR – 0.28Ω, deviation: -12%

Microphone amplifier board - before and after

Dial Cord Restringing

The old dial string in this unit was loosened. I replaced it with a new dial cord (the most tedious job on any vintage receiver).

The old and new dial cord

Dial, Meter, and Stereo Indicator Lamps

The old dial incandescent lamps were replaced with new warm white LED lamps (festoon type). The old meter lamps were also replaced with new warm white LED lamps (fuse type). Finally, the burned stereo indicator lamp was replaced with a new incandescent lamp.

New LED meter lamps

New incandescent stereo indicator lamp

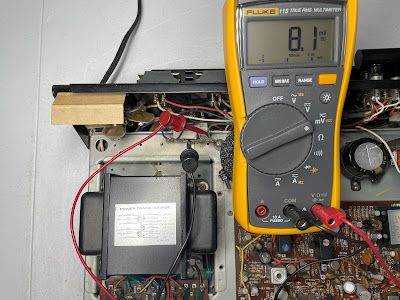

Power Amplifier Adjustment

The Bias is measured across two emitter resistors: R718 & R719 (left channel) and R768 & R769 (right channel). According to the service manual, it should be adjusted to 50mV on each channel with trimming resistors RT701 and RT751.

As I mentioned earlier, the STR-7065 does not have trimmers to adjust the DC offset on each channel. I was able to bring it down to an acceptable level by replacing the OEM Sony transistors in the differential amplifier with new close-matched Fairchild transistors (see the "Power Amplifier/Power Supply Board" section for details).

Bias on the left and right channels after restoration

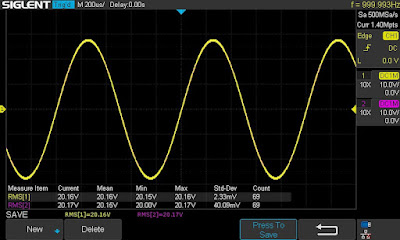

Output Power Test

The final output power test was performed at the end of my restoration. The receiver was loaded with a low inductance 8Ω/100W dummy resistor for each channel. The oscilloscope was connected across the speaker terminals and a sine-wave signal of 1kHz was applied to the AUX jacks. The output sine-wave signal was perfectly symmetrical on both channels with no clipping up to 23.05 VRMS (left channel) and 23.33 VRMS (right channel). It corresponds to the output power of 66.4W on the left channel and 68.0W on the right channel.

Output power test

As usual, all the knobs and the front panel were gently cleaned in warm water with dish soap. All controls have been cleaned with DeoxIT 5% contact cleaner and lubricated with DeoxIT FaderLube 5% spray. The wood case was treated with Howard's Restor-A-Finish.

The final result can be seen in the photos below. It looks and sounds great! Please watch a short demo video at the end of this post. Thank you for reading.

Sony STR-7065 - after restoration

_before%20servicing.jpg)

_after%20servicing.jpg)

_before%20servicing.jpg)

_after%20servicing.jpg)

_before%20servicing.jpg)

_after%20servicing.jpg)

_before%20servicing.jpg)

_after%20servicing.jpg)

_before%20servicing.jpg)

_after%20servicing.jpg)

_before%20servicing.jpg)

_after%20servicing.jpg)