Unit: AM/FM Stereo Receiver

Manufacturer: Marantz

Model: 2230

SN: 41141

I bought this receiver about a year ago from the original owner. It has been sitting in his basement for some time and was rather dirty inside. However, it is still in perfect cosmetic condition without any scratches or dents. Marantz 2230 is one of my favorite entry-level receivers. It was introduced in 1972 and delivers 30 watts per channel into 8 ohms with total harmonic distortion under 0.5%. The optional walnut veneer cabinet for this model is WC-22. The list price in 1972 was $349.95.

According to the owner, this receiver was serviced only once about 20 years ago. He said that only the push button switch and dial bulbs were replaced. So, I decided to fully restore this receiver and service all boards including the tuner section. Below are some photos I took during my restoration process, complete with comments and recommendations.

Regulated

Power Supply Board P800

The

power supply board provides +14V DC to the Tuner and +35.6V DC to the phono and

pre-amplifiers. The large wire wound resistor (150 Ohm, 5W) on this board runs very hot under normal operating conditions. Also, it sits very close to other electronic components and often touches the wires soldered to transistor H801. I

replaced the original resistor with a new IRC / TT Electronics wire wound resistor.

The new resistor is smaller, does not have bulky corners, and has a rated

power of 7W instead of 5W. It reduces heat stress and discoloration of PCB.

The H801 transistor was removed from the heat sink, degreased, and tested on an Atlas DCA55 semiconductor analyzer. The DC current gain was in spec according

to the datasheet. I replaced the old thermal pad with a new Sil-pad and mounted the H801 back on the heat sink. Two

original diodes H804 & H805 were replaced with the modern fast recovery rectifiers

UF4005. All electrolytic capacitors were replaced with low impedance and

high-reliability Nichicon UPW/UPM caps. Finally, the voltage between the pin J808

and the ground was checked and adjusted to +35.6V.

I

tested all original e-caps removed from the power supply board and only one

capacitor C807 was outside of the factory capacitance tolerance +/- 20%. Not too

bad for 46 years old gear!

Test

results on original capacitors removed from the power supply board:

C803:

rated capacitance – 470uF, measured – 445uF, deviation: -5%

C804: rated capacitance – 330uF, measured – 384uF, deviation: +16%

C805: rated capacitance – 470uF, measured – 542uF, deviation: +15%

C806: rated capacitance – 330uF, measured – 386uF, deviation: +17%

C807: rated capacitance – 3.3uF, measured – 4.9uF, deviation: +49%

C804: rated capacitance – 330uF, measured – 384uF, deviation: +16%

C805: rated capacitance – 470uF, measured – 542uF, deviation: +15%

C806: rated capacitance – 330uF, measured – 386uF, deviation: +17%

C807: rated capacitance – 3.3uF, measured – 4.9uF, deviation: +49%

Regulated Power Supply board P800 - before and after

Phono

Amplifier Board P700

The

phono stage in the 2230 model is known by many audiophiles as one of the best in

class. Signals from the phono jacks are applied to phono amplifier board P700

consisting of transistors H701, H703, and H705, and temperature compensating

diodes H707 and H709. The NPN transistor 2SC458LG installed on this board has a

bad reputation as a potential source of the noise. I replaced two 2SC458LG

transistors (H705 and H706) with modern low-noise Fairchild KSC1845. The new

transistors were gain matched within 1%. The temperature compensating diode

H709 was replaced with two 1N4448 diodes soldered in series. The other two diodes

H707 and H708 were replaced with single 1N4448 diodes. The original tantalum

capacitors C703 and C704 were replaced with low leakage Nichicon UKL caps. The

e-cap C713 was replaced with a low impedance and high-reliability Nichicon UPM

capacitor. The axial e-cap C011 soldered between the pin J706 and ground was

replaced with a new Vishay axial capacitor.

All

original e-caps removed from the phono amplifier board were

within the factory capacitance tolerance +/- 20%.

Test

results on original capacitors removed from the phono amplifier board:

C703:

rated capacitance – 22uF, measured – 25uF, deviation: +14%

C704:

rated capacitance – 22uF, measured – 25uF, deviation: +14%

C713: rated capacitance – 100uF, measured – 119uF, deviation: +19%

C011: rated capacitance – 220uF, measured – 258uF, deviation: +17%

C713: rated capacitance – 100uF, measured – 119uF, deviation: +19%

C011: rated capacitance – 220uF, measured – 258uF, deviation: +17%

Phono Amplifier board P700 - before and after

Tone

Amplifier Board P400

Pre-amplifier

board P400 consists of two stages of direct-coupled amplifiers (H401 and H403,

H405 and H407). The tone control unit is sandwiched between these two

direct-coupled amplifiers. This board has 8 low leakage electrolytic

capacitors: C403/C404, C407/C408, C410/C411, and C414/C415. I replaced all

those e-caps with high-quality film polyester WIMA MKS2/MKS4 caps. The remaining 3

e-caps (C405, C406, and C409) were replaced with low impedance and

high-reliability Nichicon UPW capacitors. No transistors were replaced on this

board. The test results on all e-caps removed from the board are below. 5 original

e-caps are outside of the factory capacitance tolerance. It clearly

shows the importance of replacing all electrolytic capacitors in any vintage

gear!

Test

results on original capacitors removed from the tone amplifier board:

C403:

rated capacitance – 1uF, measured – 1.06uF, deviation: +6%

C404:

rated capacitance – 1uF, measured – 1.06uF, deviation: +6%

C405: rated capacitance – 10uF, measured – 15uF, deviation: +50%

C406: rated capacitance – 10uF, measured – 14uF, deviation: +40%

C407: rated capacitance – 3.3uF, measured – 4.6uF, deviation: +39%

C408: rated capacitance – 3.3uF, measured – 4.4uF, deviation: +33%

C409: rated capacitance – 100uF, measured – 98uF, deviation: -2%

C410: rated capacitance – 3.3uF, measured – 3.7uF, deviation: +12%

C411: rated capacitance – 3.3uF, measured – 4.3uF, deviation: +30%

C414: rated capacitance – 1uF, measured – 1.15uF, deviation: +15%

C415: rated capacitance – 1uF, measured – 1.18uF, deviation: +18%

C405: rated capacitance – 10uF, measured – 15uF, deviation: +50%

C406: rated capacitance – 10uF, measured – 14uF, deviation: +40%

C407: rated capacitance – 3.3uF, measured – 4.6uF, deviation: +39%

C408: rated capacitance – 3.3uF, measured – 4.4uF, deviation: +33%

C409: rated capacitance – 100uF, measured – 98uF, deviation: -2%

C410: rated capacitance – 3.3uF, measured – 3.7uF, deviation: +12%

C411: rated capacitance – 3.3uF, measured – 4.3uF, deviation: +30%

C414: rated capacitance – 1uF, measured – 1.15uF, deviation: +15%

C415: rated capacitance – 1uF, measured – 1.18uF, deviation: +18%

Tone Amplifier board P400 - before and after

Power

Amplifier Board P750

I recommend paying attention to all electrolytic

capacitors on this board if you need to service it. I found at least three

errors in the schematic concerning the e-caps C751, C753, and C757. The

schematic shows the e-cap C751 as 0.47uF/25V despite the original capacitor installed

on the board being 1uF/50V. This is a signal path capacitor. I replaced this cap

with a high-quality film polyester WIMA MKS2 cap with the same rated capacitance

and voltage as the original, i.e. 1uF/50V. The next capacitor in question is C753.

The schematic shows this position as 1uF/50V despite the original capacitor

being 10uF/35V. I replaced this cap with a Nichicon UPW e-cap with the same rated

capacitance as the original but with an increased voltage to 50V. The last capacitor

in question is C757. The schematic shows this position as 22uF/35V despite the original capacitor being

22uF/50V. So, the installed e-cap has the same capacitance as the schematic shows

but with a higher rated voltage. I

replaced this cap with a Nichicon UPW e-cap keeping the same rated

capacitance and voltage as the original. The remaining e-caps C752, C754, and C755 were

replaced with Nichicon UPW/UPM caps. The test results on all e-caps removed

from the board are below. Only 2 original capacitors out of 12 are still in

factory capacitance tolerance.

Test

results on original capacitors removed from the power amplifier board:

C751-L:

rated capacitance – 1uF, measured – 0.96uF, deviation: -4%

C751-R:

rated capacitance – 1uF, measured – 0.96uF, deviation: -4%

C752-L: rated capacitance – 100uF, measured – 127uF, deviation: +27%

C752-R: rated capacitance – 100uF, measured – 132uF, deviation: +32%

C753-L: rated capacitance – 10uF, measured – 15uF, deviation: +50%

C753-R: rated capacitance – 10uF, measured – 15uF, deviation: +50%

C754-L: rated capacitance – 47uF, measured – 60uF, deviation: +28%

C754-R: rated capacitance – 47uF, measured – 61uF, deviation: +30%

C755-L: rated capacitance – 47uF, measured – 59uF, deviation: +26%

C755-R: rated capacitance – 47uF, measured – 62uF, deviation: +32%

C757-L: rated capacitance – 22uF, measured – 29uF, deviation: +32%

C757-R: rated capacitance – 22uF, measured – 28uF, deviation: +27%

C752-L: rated capacitance – 100uF, measured – 127uF, deviation: +27%

C752-R: rated capacitance – 100uF, measured – 132uF, deviation: +32%

C753-L: rated capacitance – 10uF, measured – 15uF, deviation: +50%

C753-R: rated capacitance – 10uF, measured – 15uF, deviation: +50%

C754-L: rated capacitance – 47uF, measured – 60uF, deviation: +28%

C754-R: rated capacitance – 47uF, measured – 61uF, deviation: +30%

C755-L: rated capacitance – 47uF, measured – 59uF, deviation: +26%

C755-R: rated capacitance – 47uF, measured – 62uF, deviation: +32%

C757-L: rated capacitance – 22uF, measured – 29uF, deviation: +32%

C757-R: rated capacitance – 22uF, measured – 28uF, deviation: +27%

The trimming resistors used to adjust the bias (R765) and clipping level (R760) were replaced with new Bourns

potentiometers. The emitter resistors

R774 and R775 were replaced with modern Vishay wire wound resistors with

increased rated power.

Power Amplifier board P750 - before and after

Power

Transistors

All

four power transistors H001 thru H004 were removed, cleaned, and tested with

Atlas DCA55 semiconductor analyzer. The DC current gain was in spec according

to the datasheet. However, it should be noted that Atlas DCA55 semiconductor analyzer only provides an accurate reading for DC current gain on low-power transistors. A high-power transistor requires a much higher collector current and collector-emitter voltage to accurately measure its current gain. However, it is still a very useful device for comparing transistors of a similar type for the purposes of gain matching or fault-finding.

I applied a fresh thermal compound and replaced the old

thermal pads with new Mica ones which is always a good idea when

working on any vintage receiver. A new thermal compound was also applied to the

thermal tracking diodes H005 and H006.

Power transistors tested with Atlas DCA55 semiconductor analyzer

AM Tuner

Board P150

The

AM tuner board has 12 electrolytic capacitors: C161, C162, C164, C166, C171, C173,

C175, C178, C180, C181, C183, and C184. All of them except e-cap C184 have the

same capacitance and voltage. I replaced all of them with low impedance and

high-reliability Nichicon UPW capacitors. The e-cap C184 installed on this

board is 100uF/10V and was also replaced with a Nichicon UPW cap. Watch out for e-cap C183. The silkscreen is backward. The + side of the C183 cap goes to the chassis ground.

AM Tuner board P150 - before and after

MPX

Stereo Decoding Amplifier Board P300

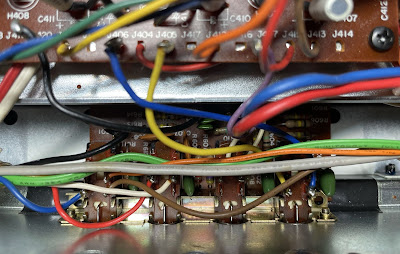

This

is the most difficult board in Marantz 2230 to work on. It is mounted on a chassis under the AM tuner board. Due to the engineering design, there is very

limited space to work on here. The electrolytic capacitor C324 was replaced with a high-quality film polyester Nichicon cap. Four low leakage e-caps C331 thru C334

were replaced with low leakage Nichicon UKL caps. The remaining e-caps were replaced

with Nichicon UPW caps.

MPX Stereo Decoding Amplifier board P300 - before and after

FM

Detector Board P500

The

FM detector board has 6 electrolytic capacitors: C503, C508 thru C511, and

C514. I replaced two e-caps C509 and C510 with low leakage Nichicon UKL caps.

The remaining four e-caps were replaced with Nichicon UPW caps.

FM Detector board P500 - before and after

Muting

Control Amplifier Board P550

This

board has only two electrolytic capacitors: C554 and C559. The C554 cap was

replaced with the Nichicon UPW cap while the C559 with low leakage Nichicon UKL

cap.

Muting Control Amplifier board P550 - before and after

Filter

and Coupling capacitors

The

original filter capacitor C007 is rated at 4700uF/80V. Two

coupling capacitors C008 and C009 are rated at 2200uF/63V. I replaced the

filter cap with a 4700uF/80V Nichicon LKG cap specially designed for high-grade audio equipment. The modern capacitors are usually much smaller, and a new

clamp is needed to securely hold them. I replaced the old clamp with a new Kemet PYC6041

clamp, which did the job. The coupling capacitors were replaced with 2200uF/80V

Nichicon LKG series. No new clamps are needed for coupling caps since both old

and new caps have the same diameter.

Old and New Filter Capacitors - note that both caps have the same rated capacitance and voltage

New filter and coupling capacitors installed

Dial lamps and Vellum paper

I replaced old incandescent dial bulbs with warm white LED lamps to maintain the original look and decrease heat. The old yellowish vellum behind the dial scale was replaced with new heavyweight clear vellum paper. In addition, I replaced the original bulb behind the FM/AM signal meter with a warm white LED lamp. The old vellum behind the FM/AM signal meter was replaced as well.

Dial scale removed

Old incandescent dial bulbs - one original bulb was missing

Signal meter with new vellum installed

Controls Cleaning and Lubricating

Both BALANCE and VOLUME pots in Marantz 2230 have great access for cleaning from the back side of the unit. The SELECTOR switch can also be very easily cleaned when the bottom plate is removed. However, the access to the BASS, MID, and TREBLE pots, as well as four switches (Low/High Filter, Loudness, Muting) is limited even from the back side. To properly clean all these pots and switches one should take apart the tone control unit assembly P450. To do this the faceplate should be removed from the chassis and three nuts holding the BASS, MID, and TREBLE pots unscrewed. It is pretty easy to do and the unit assembly P450 can be easily released for cleaning.

All controls have been cleaned with DeoxIT 5% contact cleaner and lubricated with DeoxIT FaderLube 5% spray.

Tone control unit assembly P450 - released from the chassis for cleaning

Switch unit assembly P600 (Low/High Filter, Loudness, Muting)

Audio Adjustments

All audio adjustments are clearly described in a service manual.

I adjusted the idle current to ~5mV on each channel according to the service manual (connect a multimeter across the resistor R774, between pins J757 and J758).

To adjust a clipping level I connected my oscilloscope across the speaker terminals and applied a sine-wave signal of 1 kHz to the AUX jacks. A low inductance 8Ω/100W dummy resistor was used as an output load. The trimming resistor R760 was adjusted for equal clipping.

I connected the oscilloscope to the TAPE OUT jacks to adjust the clipping level on the phono amplifier. The function generator was connected to the PHONO jacks and a sine-wave signal of 1 kHz was applied. The trimming resistor R708 was adjusted for equal clipping. For the other channel, the trimming resistor R709 was adjusted.

As usual, all the knobs and the faceplate were gently cleaned in warm water with dish soap.

The final result can be seen in the photos below. Please watch a short demo video at the end of this post. Thank you for reading.

Marantz 2230 - before restoration

Marantz 2230 - after restoration

Demo video after repair & restoration

Thank you for sharing your detailed restoration of the 2230. How did you remove the rust from the interior metal covers? They look like new in your "after" pictures... Thanks,

ReplyDeleteNothing special. I removed the interior metal covers, sanded them with a sandpaper and that's it. For other interior metal parts I used a combination of sanding and isopropyl alcohol. You just need to be very careful and patient. I used the fine and ultra-fine grit sandpaper.

DeleteThank you for the tip!

DeleteDear Oleg, thank you so much for this fabulous description of the Marantz 2230. Just on question concerning the phono stage:do you see any problem operating a Moving Iron cartridge (Nagaoka) on a Thorens turntable with the Marantz? Many thanks from Austria, Gunter

ReplyDeleteHello,

DeleteI don't see any issues here. According to owner's manual "the phono stage in Marantz 2230 is intended for use with magnetic phono cartridges requiring a standard 47,000-ohm resistive load. Phono signals of up to 100mV can be handled without overloading".

Thanks and good luck for your future projects.

ReplyDeleteOleg, I have this model Marantz amp and it smoked; unfortunately, this happened right before the Pandemic hit. I'm in Savannah and am wondering what a cost range would be for a restoration. Im trying to determine whether to sell my current amp and replace it or restore it. Your thoughts would be sincerely appreciated.

ReplyDeleteHello DocWatsonFan, the 2230 model is a great receiver and very popular among collectors and vintage stereo enthusiasts. If you are the original owner and your unit is still in good cosmetic condition, then I would recommend restoring it. E-mail me at repair@olegvintageaudio.com for more details.

DeleteMr. Oleg,

ReplyDeleteI'm currently in the process of working on a 2230 and this page has been very helpful, thank you for sharing.

I was wondering if you had a part number for the Bourns potentiometers you used to replace the trimming resistors used to adjust the bias (R765) and clipping level (R760) on the P750 power boards.

Thank you again.

Hi, I used the following Bourns potentiometers in my restoration: 3386F-1-471LF (R765, Bias), and 3386F-1-104LF (R760, Clipping level).

DeleteThank you, sir.

DeleteHi Oleg,

ReplyDeleteWhich thermal pads do you recommend for the power transistors. If you have a part number that would be great. Also, what is your recommended thermal compound?

Thanks for making this incredible resource available to the public. I read all of these posts as I find them interesting.

Hi, I recommend the Mica thermal pads (Digikey PN 56-03-8G) and Wakefield Thermal Compound (type 120 Silicone).

DeleteThank you. Do you happen to know the original power rating of the emitter resistors R774 and R775? I'm not able to tell what it is from the part or the service manual. I was going to use 5W but I'd rather be safe than sorry. Thanks.

DeleteThe original R774/R775 emitter resistors are 3W wirewound resistors. I would recommend replacing them with Vishay 5W wirewound resistors (PN AC05000002407JAC00).

Delete