Unit: Stereo Cassette Tape Deck

Manufacturer: Onkyo

Model: TA-630D

SN: 10062943

I bought this cassette tape deck about two years ago from the original owner for just $25. The deck is in excellent cosmetic condition and there are only two almost invisible minor scratches on the faceplate. The owner told me that the last time he played the music on this deck was at least ten years ago. We met in a public place and I was not able to check whether it is working or not. But it was still a great deal since he wanted just $25 for it! I usually don't buy or restore vintage tape recorders because they often have problems with the transport mechanism, which I am not an expert in. But this tape deck was cheap, almost in perfect cosmetic condition, and most importantly for me, it has two large black VU meters! I am in love with vintage gears having VU meters. So, I bought it hoping to restore and keep it in my personal collection.

The Onkyo TA-630D is a stereo cassette deck with Dolby B noise reduction. It has 2 heads, belt-driven single-capstan transport, manual tape type selection handling normal, chrome and ferro-chrome tapes with additional manual equalization selection, and two large analog needle meters. The frequency response is from 30Hz to 18kHz on ferro-chrome tape and the signal to noise ratio is 68dB. It was manufactured from 1978 to 1980 with a list price of $350.

Belt Replacement

When I removed the top cover to check this unit inside I immediately noticed that we have a big problem here. The flat belt (Motor-Flywheel) and square-cut belt (Motor-pulley) have degraded so badly over time that both turned into sticky mush. Well, it looks like it wouldn't be an easy project. I checked online to get some guidance on how to replace these belts on this unit but with no success. There are just a few videos posted on YouTube about servicing Onkyo TA-630D but without good instructions for belt replacement. The service manual is also not very helpful for the belt replacement process. So, I decided to replace both belts based on my knowledge and experience with other cassette decks I restored before.

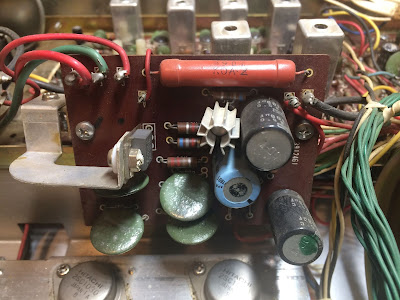

Further investigation revealed that this is definitely not a service-friendly cassette deck. I didn't find a way to replace two belts without disassembling and removing the metal bracket holding the motor and flywheel. Therefore, I initially removed the motor to clean its pulley from the sticky mush. This was an easy step but took some time to thoroughly clean the motor pulley from this messy stuff.

Sticky mush on the motor pulley from the old belt

Then, I tried to remove the sticky mush from the flywheel as much as possible before removing the metal bracket. I used a lot of Q-tips and isopropyl alcohol for that job.

Eventually, I unscrew four small screws, removed the metal bracket, and pulled out the flywheel. I recommend paying attention to this step and taking a lot of pictures. Don't lose the poly washer and tension spring from the flywheel!

Metal bracket holding the motor and flywheel

Metal bracket and flywheel removed

I removed the residue of the old belt from all pulleys and cleaned them with isopropyl alcohol. The old lithium grease on most metal levers was mostly dried out. I removed this grease from all parts as much as I could and applied a new white lithium grease. The FF key on this unit was stuck but eventually came free with a little extra effort. I exercised all keys to make sure that the new grease penetrated between each lever and everything works smoothly.

The new flat belt (Motor-Flywheel) was installed in two steps. First of all, I installed a flywheel back and put a new flat belt on it. Then I installed the metal bracket trying not to damage a new flat belt and secured it with four screws. This step is the most critical one because the working space is really very limited here and a new belt tends to come off from the flywheel. So, take your time and don't rush at this step. When the metal bracket was successfully installed I mounted the motor on it and secured it with two screws. Then, using a pair of tweezers I was able to hang the belt to the motor pin.

A new flat belt (Motor-Flywheel) installed

A new square cut belt (Motor-pulley) is fairly easy to install now since everything is mostly assembled. Double check the service manual to figure out how this belt should be installed. I used a pair of tweezers and with some patience was able to hang this belt as well.

A new square cut belt (Motor-pulley) installed

Cassette chassis assembled - back side

The last belt to replace is a counter belt. To access this belt one should remove the cassette door, cassette case, and cassette case plate. I didn't have any trouble removing these parts since the design is rather simple and it was intuitively clear what to do at each step.

Cassette door, case, and plate removed

Surprisingly but this belt survived and was still in pretty good condition. I vacuumed the deck chassis, cleaned the capstan, pinch roller, and both heads with isopropyl alcohol. Then applied a new white lithium grease to the rubbing metal parts and installed a new counter belt.

Clean chassis with new counter belt installed

For reference, I used the following belts in Onkyo TA-630D (Russell Industries, Inc. Cross-reference manual):

Flat belt (Motor-Flywheel) - FRZ7.5

Square cut belt (Motor-pulley) - SCQ8.2

Counter belt - SCY7.0

VU Meter Lamps

The lamp in the right channel VU meter has burned out and I decided to replace it with a new axial lamp. The meter is attached to the metal plate with double-sided tape. I used an X-ACTO #2 Knife to separate the meter from the metal plate. Pay attention to this step and don't apply too much force trying to separate it from the metal plate. Instead, try to carefully trim the double side tape with a proper knife/blade. The meter can be easily damaged due to extensive stress.

The lens is attached to the meter body with transparent tape which is not so easy to recognize at a first glance. I peeled off part of this transparent tape from the sides and carefully separated the lens from the meter body. According to the service manual, the original VU meter lamp is an axial 6.3V/100mA lamp. I replaced it with a new axial 6V/100mA lamp. The original lamp is a frosted bulb with a green tint whereas a new one is clear glass. I didn't find a suitable material to replicate the original green filter. The obvious option would be a green transparent tape wrapped around the lamp. But in that case, the tape would suffer from the extensive heat. So, I decided to leave it alone but also replace the original axial lamp from the left VU meter. At least both VU meters would match each other. Please leave a comment under this post if you have a better solution for a green filter.

VU Meters - the axial lamp in the right meter is burned out

Each VU meter is attached to the metal plate with a double-sided tape

Transparent tape on the sides of the VU meter lens

Right VU meter - burned axial lamp

Right VU meter - new axial lamp installed

I cleaned all the knobs and the faceplate in warm water with dish soap. All pots and switches have been cleaned with DeoxIT 5% contact cleaner and lubricated with DeoxIT FaderLube 5% spray.

The final result can be seen in the photos below. The transport mechanism is working properly again, all levers move smoothly and I am enjoying how it looks and plays music. Thank you for reading.

Onkyo TA-630D - after restoration